|

MONOd' and MONOforce

QUALITY, PRECISION, STRENGTH, AND CONVENIENCE

The integrated MONOd’ and MONOforce toolholders

represent an ideal solution to equip any type of machine tool with HSK

63, DIN AD+B, BT AD+B and CAT base arbors, guaranteeing the benefits of

a high quality, high precision and ultra-tight tool, with a price that

is highly competitive on the market. The MONOd’ program includes ER

collet chucks, Weldon, mill holders, Morse tapers, and tapping chucks.

The MONOforce ultra-tight line involves tool housing dimensions of Ø

.47",

.79" and 1.26", and allows for the tool to be tightened from Ø .12" to

.98"

with the use of standard reduction bushes. MONOforce is also available

in kits complete with reduction bushes and tightening spanner.

|

|

TOPRUN

HIGH SPEED, BALANCING, AND PRECISION

A balanceable monobloc toolholder system that

guarantees high precision in high speed machining on modern machining

centers. The concentricity between the base arbors HSK 63, DIN, BT and

CAT and the seat of the tool is always less than 3 µm. The advantages of

using TOPRUN are the precision and the better quality surface finishing,

a longer life of the tool and the machine spindle, as well as reduced

costs and times and less noise and vibrations. The TOPRUN toolholder

line includes ER collet chucks, Weldon, mill holders, and FORCE, an

ultra-tight milling force.

|

|

MODULHARD'ANDREA

MODULARITY AND HIGH PRECISION

High precision modular toolholders for machine tools

and machining centres that allow for boring, milling, drilling, and

tapping operations to be carried out with extreme flexibility and

rigidity. The cylindrical-conical coupling comes in nine sizes, ensuring

the interchangeability of all the elements of the system that includes

the base arbors HSK, DIN, BT, CAT and Polygon-shank, toolholder

extensions, reductions, and adapters. The complete boring program for

machining diameters from .10" to 110.24", complete the MHD’ line complete

with roughing double-bit heads and centesimal and micrometric Testarossa

finishing heads with a 2µm sensitivity adjustment.

|

|

GRINTA and MCD'

MILLING AND TURNING OPERATIONS

D’Andrea solutions for

milling and turning operations that use cutting geometries with ISO

inserts. The GRINTA program takes advantage of the perfect coupling

concentricity and the extreme resistance to torsion of the MHD’ modular

attachment. The arbors from Ø .63" to 1.26" are built with the MHD’

cylindrical-conical attachment and threaded end, while the one with Ø

from 1.57" to 2.48" are made with the MHD’ integral attachment.

The MCD’ line includes lathe tools and toolholders, made in accordance

with HSK-A63 standards with ICTM construction tolerances recommended for

the application on MULTI-TASK machines. The program is produced in

modular versions, with HSK attachment and interchangeable insert holder

seats and complete with toolholders that permit the mounting of standard

lathe tools.

|

|

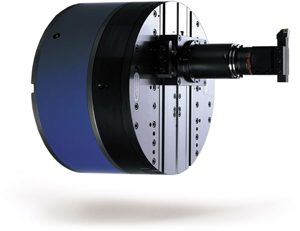

TA-CENTER

TURNING OPERATIONS ON ALL MACHINING CENTRES

Boring and facing heads with automatic balancing,

that allow for turning operations with fixed pieces on all machining

centers. Built in five models with Ø of 3.15", 3.94", 4.92", 6.30", and

7.87",

they can be easily applied on any machining center set up with a command

unit for controlling the feed of the toolholder slide. The dimensions,

structure, and weight of some models, allow for the TA-CENTER to be

positioned even in the tool magazine area of small machining centers and

loaded by the tool changer on the spindle of the machine. The simple

application of the U-DRIVE command unit connected to the machine NC,

allow for all types of operations to be performed including turning,

cylindrical and conical boring, facing, threading, corner rounding, and

spherical operations.

|

|

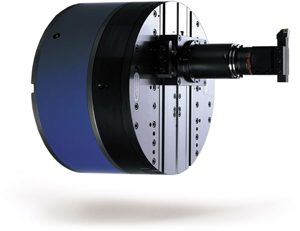

TA-TRONIC

TURNING OPERATIONS ON ALL MACHINE TOOLS

Boring and facing heads with automatic balancing,

that allow for turning operations with fixed pieces on all machine

tools. Built in four models with Ø of 3.94", 4.92", 6.30", and 7.87", they

can be easily applied manually or automatically on boring machines,

machining units, and special machines. Connected to the NC of the

machine tool they make it possible to perform all types turning,

cylindrical and conical boring, facing, threading, corner rounding, and

spherical operations. Application on machines where they cannot be

connected to the NC, may be made by managing the motor with a practical,

simple, and economical positioner complete with a wireless

REMOTE–CONTROL.

|

|

U-TRONIC

"SUPER SIZED" PERFORMANCE

Medium and large sized boring and facing heads,

which allow for turning operations to be made with fixed pieces on all

machine tools. Built in various models from Ø of 14.17" to 63", they

can be applied manually, automatically, and with pallet systems on

boring machines and special machines. Connected to the NC of the machine

tool, they make it possible for all types of operations to be made

including turning, cylindrical and conical boring, facing, threading,

corner turning, and spherical operations. Managing machines where a

connection to the NC is impossible, may be made using a positioner with

a wireless REMOTE–CONTROL. Special versions of U-TRONIC, with two slides

or with counterweights for self-balancing may be supplied upon request.

|

|

U-COMAX

UNIT AND TRANSFER SOLUTIONS

U-Comax boring and facing heads are axial command

heads designed to be used on transfer machines, machining units, and

special machinery. Even during rotation the feed control of the

toolholder slide is commanded by a U-Drive drive unit, mounted behind

the spindle and managed directly by the NC of the machine tool. U-Comax

heads are used for inner facing, outer facing, back-facing, inner and

outer turning operations, grooves, phonographic grooves, cylindrical and

conical threading, conical and variable boring, concave and convex

corner rounding, through interpolation with the other the machine axes.

|

|

AUTORADIAL

FOR AUTOMATIC FACING

Facing heads with automatic feed and rapid return

of the slide, without stopping or inversion of the machine tool spindle.

Built in three models, AR100, AR125, and AR160, that are easily applied

on machining centers, processing units, and on NC machines and do not

require any electronic interface or servo drive. They automatically

perform a work cycle of facing, back-facing, phonographic grooves on

flanges, internal or external seats for snap rings or O-Rings. Six feeds

of the interchangeable tool holder slide are available, upon request.

|

View our

D'Andrea videos on YouTube

View our

D'Andrea videos on YouTube