|

|

|

|

|

|

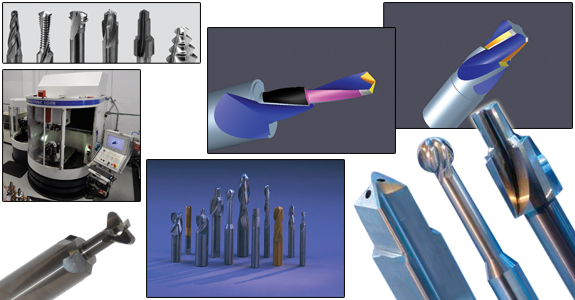

A state-of-the-art precision grinding division established to create industry-leading carbide tooling solutions. Within the climate controlled walls of TEC Tooling Grinding Division, world-class CNC grinding technology is applied to a comprehensive standard product offering, in addition to application-driven carbide specials. Fully automated multi Axis CNC machines produce advanced tooling 24 hours a day - including lights out! Linear drives with incredible speed and acceleration produce flawless tool finishes and improved accuracy of up to 50% over traditional CNC grinding machinery. From simple modifications to standard lines of tooling, to completely engineered tooling solutions - TEC Tooling has the skill and experience to deliver quality products to increase productivity. |

|

Specialty Application Tooling: • Solid Carbide Tooling • Custom Drills & Taper Mills • Virtually Unlimited Form Tools • Coolant Through G-Drills, Step Drills • Special Radii • Reamer • Jig Boring Tools • Forming Tools • Dovetail Cutters • Porting Tools • Coolant Through • Advanced Coating Capability |

|

|

NEW! Carbide End Mill Program |

NEW!

ORION End Mills For Machining Aluminum |

NEW!

STRATUS End Mills For Dynamic Milling |

Specialty Application Tooling |

|

|

|

|

|

Specialty Application Tooling |

|

Straight Flute Drills |

High Performance Spiral Drills |

Square End Mills |

|

Tapered End Mills |

||

|

|

||

|

Ball Nose End Mills |

Reamers |

|